Blasting FAQs

What causes ground vibration and how is it measured?

When a blast detonates, energy radiates in all directions as wave motion, like a ripple created in a lake when a stone hits the water. This wave travels mainly along the surface at 5,000 to 20,000 feet per second. Its energy level falls off rapidly with distance and is normally undetectable by most people beyond several thousand feet. Because explosives are expensive and vibration represents wasted energy, it is to the blaster’s advantage to minimize ground vibration.

How is ground vibration controlled?

Blasters control ground vibration by limiting the weight of explosives detonated within any 8-millisecond period of time. They use millisecond-delay detonators (blasting caps) to separate the firing time of each hole. A typical 50-hole blast, therefore, is actually 50 smaller, separate explosions.

What is “airblast” and how is it measured?

When a blast is detonated, some energy is lost to the atmosphere as noise or concussion. This is caused by gases venting through cracks and the motion of rock on top and in front of blastholes. The resulting sudden increase in air pressure is called airblast. Like ground vibrations, airblast levels decrease rapidly with distance. However, airblast travels only at the speed of sound, about 1,100 feet per second, depending on air temperature, and can be greatly influenced by wind direction and speed. Atmospheric temperature inversions can also influence airblast by bending it back towards the earth and focusing its energy several miles away. Airblast is measured with a special microphone connected to a seismograph. The most common units of airblast measurement are pounds per square inch (PSI) and decibels (dB).

How is airblast controlled?

Airblast is controlled by placing stemming material (drill cuttings or crushed stone) above the explosives in the blasthole and by not loading explosives into parts of holes with cracks, voids or mud seams.

What are the legal limits for ground vibration and airblast?

The United States Bureau of Mines conducted extensive research over a 35-year period and has published recommendations that limit blast-induced ground vibration and airblast to protect homes and other structures from damage. The Division of Mineral Resources has incorporated these recommendations into mining permits as special permit conditions for mines across the state.

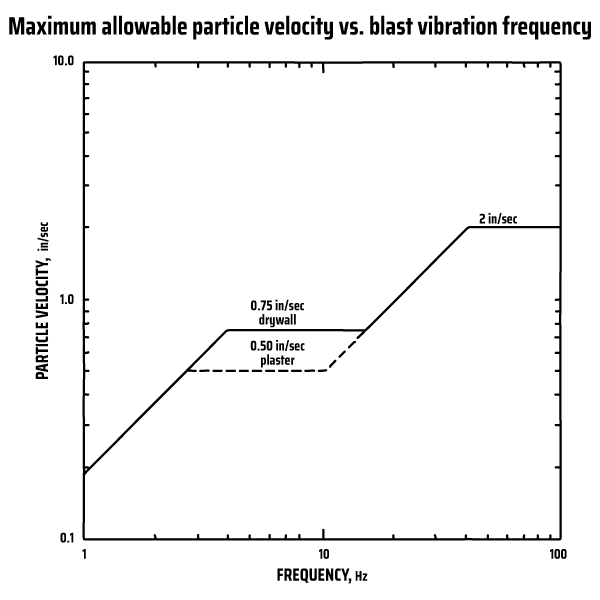

Per Wisconsin Code SPS 307.44, an airblast may not exceed 133 peak dB at the location of any dwelling, public building or place of employment outside the controlled blasting site area. The blaster shall use the ground vibration limits specified below to determine the maximum allowable ground vibration.

Seismographs measure ground vibration in terms of particle velocity, which is the speed, in inches per second, at which ground particles oscillate as the wave passes. Beyond several thousand feet, ground movement is only a small fraction of an inch.

Who do I call with blasting questions?

To give us feedback directly, or for a tour of operations, call our main office (262) 251-1520 and ask for Nate Swinton. Contact Charlene Vogt with the Wisconsin Department of Safety and Professional Services at Charlene.Vogt@wisconsin.gov for regulatory questions.